Advanced Production Techniques: In-Mold Decorations Explained

Advanced Production Techniques: In-Mold Decorations Explained

Blog Article

Mastering In-Mold Decorations: Methods, Patterns, and Best Practices for Optimal Outcomes

In the world of manufacturing, the art of in-mold designs stands as an essential facet of item style and production. As markets constantly seek innovative methods to enhance visual charm and functionality, mastering the ins and outs of in-mold decorations has actually emerged as a vital capability. From picking the ideal products to incorporating cutting-edge design trends, the journey towards accomplishing optimum cause this domain name is diverse. By delving into the techniques, patterns, and best techniques that underpin successful in-mold design procedures, organizations can open a world of possibilities that not just raise the visual attraction of their products yet additionally simplify manufacturing efficiency and reinforce consumer involvement.

Material Selection

Product selection is a crucial aspect of grasping in-mold designs, as it straight affects the quality and toughness of the last product. When picking products for in-mold decors, it is important to take into consideration elements such as compatibility with the molding procedure, the preferred visual outcome, and the ecological problems the product will certainly deal with.

Furthermore, the picked product must have excellent adhesion properties to make certain that the decor sticks securely to the substrate during the molding process. Bond in between the design and the product is critical for avoiding delamination and ensuring durable visual charm. In addition, products with high warmth resistance are favored for in-mold decorations, especially for items that will certainly be exposed to elevated temperature levels throughout their lifecycle. By meticulously choosing the proper product for in-mold decors, producers can boost the general quality and durability of their items, meeting the assumptions of both customers and end-users.

Style Innovation

A vital aspect in progressing the area of in-mold decors is the continuous exploration and implementation of design development methods. Style development plays an essential function in boosting the visual charm, functionality, and general top quality of items manufactured making use of in-mold decoration procedures. By including ingenious layout components, manufacturers can distinguish their products in the market, draw in customers, and remain ahead of competitors.

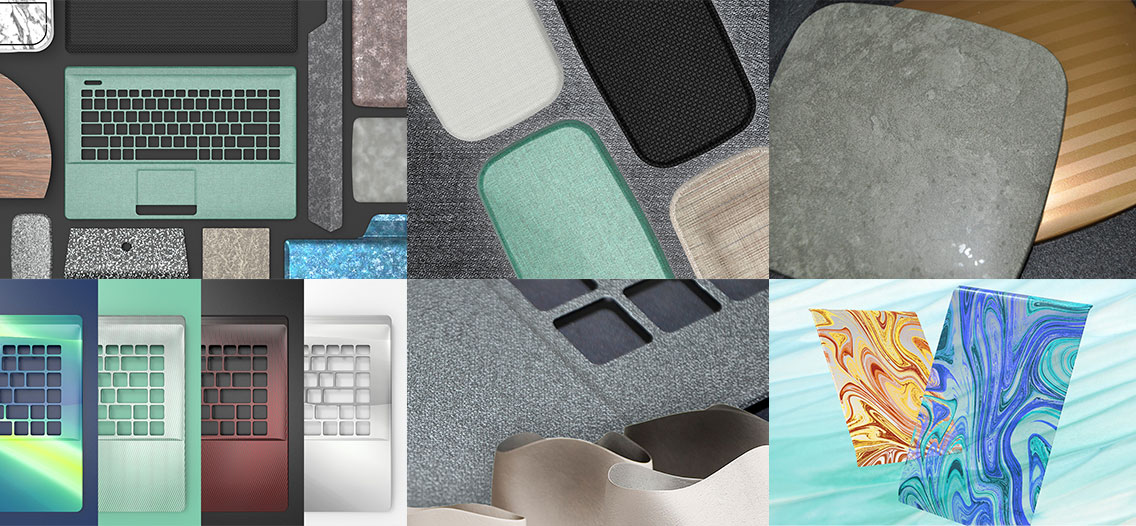

One of the vital elements of style technology in in-mold decorations is the combination of elaborate patterns, textures, and graphics that were formerly challenging to accomplish with conventional decor approaches. Advanced innovations such as 3D printing and digital layout devices make it possible for designers to produce complex and thorough styles that can be effortlessly moved onto molded components. Furthermore, the use of dynamic colors, metallic surfaces, and special impacts like gloss or matte appearances can better elevate the aesthetic charm of in-mold embellished items.

In addition, layout development prolongs beyond looks to encompass useful enhancements such as ergonomic shapes, integrated attributes, and adjustable aspects that satisfy certain customer demands. By welcoming style development, manufacturers can unlock new possibilities for product, personalization, and creativity distinction in the affordable landscape of in-mold designs.

Production Performance

Reliable manufacturing processes are vital for equating the you can find out more cutting-edge designs established in the area of in-mold designs right into high-grade completed products that satisfy market demands and consumer expectations. In the realm of in-mold decors, production effectiveness incorporates various essential elements that contribute to the general success of the production process. One critical aspect is the optimization of mold layout and tooling to ensure smooth and precise design transfer onto the final item. By fine-tuning mold and mildew setups and spending in top quality tooling materials, manufacturers can boost effectiveness and uniformity in production.

Automation not only accelerates the manufacturing procedure but also enhances precision and repeatability, leading to a much more uniform and top quality end product. In general, an all natural approach to Full Report manufacturing performance is vital in optimizing the potential of in-mold decoration techniques and achieving optimal outcomes in the affordable market landscape.

Quality Assurance Steps

What are the vital approaches for making sure strict quality control actions in the realm of in-mold decorations? Quality control measures are vital in in-mold design processes to guarantee the manufacturing of high-quality and perfect finished products.

Utilizing sophisticated innovations such as computerized assessment systems can additionally enhance the quality control procedure by providing trusted and accurate data for analysis. These systems can detect blemishes that might be missed by hand-operated examinations, thus boosting overall item high quality and consistency.

Regular training and development programs for staff members associated with the in-mold design process can also add to maintaining high-grade criteria. By informing staff on finest methods, high quality expectations, and the importance of attention to detail, firms can cultivate a culture of top quality awareness throughout the organization.

Consumer Allure

To enhance the bankability of in-mold decor products, catering and comprehending to consumer choices play an important role in identifying their charm and success. Using modification alternatives such as personalized layouts, shade variants, and textural elements can dramatically boost the charm of in-mold decor items.

Final Thought

In-mold decorations use a versatile and reliable means to enhance item looks. Mastering in-mold decorations calls for an all natural method that takes into consideration all facets of the manufacturing process to make sure success.

In the world of production, the art of in-mold decorations stands visit this website as a critical facet of product style and manufacturing. Style development plays a vital duty in enhancing the visual appeal, functionality, and overall quality of products made using in-mold decor processes.One of the key facets of design development in in-mold decors is the integration of elaborate patterns, appearances, and graphics that were previously testing to accomplish with conventional decoration approaches.Efficient production procedures are necessary for equating the cutting-edge layouts developed in the field of in-mold decorations into top notch completed products that fulfill market demands and customer expectations. Providing modification options such as personalized designs, color variants, and textural components can significantly enhance the appeal of in-mold design products.

Report this page